|

|

|

|

|

|

|

PULSAR

Cutting condition

(切削参数)

|

|

|

|

|

1.Steels

& Alloyed Steels (-HRc 20) 钢及合金钢

2.Steels & Alloyed Steels (HRc 20-30) 钢及合金钢

3.Steels & Alloyed Steels (HRc 30-40) 钢及合金钢

4..Steels & Alloyed Steels (HRc 40) -High Temperature

Alloys 钢及合金钢、高温合金

5.Stainless Steels Titaninum Alloys 不锈钢、钛合金

6.Cast Iron (General & Special) 普通铸铁及特殊铸铁

7.Aluminum Alloys 铝合金

8.Copper, Brass, Non-Ferrous Metals 铜、锡及有色金属 |

| |

|

| |

v=Cutting

speed 切削速度

n=Revolution per min. 每分钟转数

u=Feed 进给

s,=Feed per tooth 每齿进给

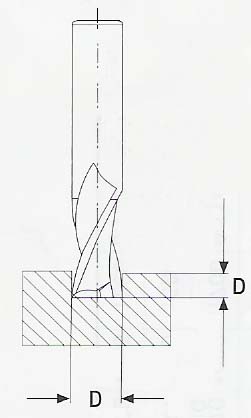

d=Cutting Diameter in mm 切削直径

z=Number of flute 刃数

π=3.14 |

| |

|

| |

v=dπn/1000

(m/min.)

n=v1000/dπ (Rev./min.)

u=s,z n (mm/min.)

s,=u/n z (mm/tooth)

|

|

| |

|

MATERIAL

GROUP

材质

|

1

|

2

|

3

|

4

|

|

CUTTING

SPEED

切削速度

|

v=35m/min.

|

v=30m/min.

|

v=25m/min.

|

v=20m/min.

|

|

d

|

z

|

n

|

s,

|

u

|

n

|

s,

|

u

|

n

|

s,

|

u

|

n

|

s,

|

u

|

|

2

|

2

|

5500

|

0.007

|

80

|

4800

|

0.007

|

70

|

4000

|

0.006

|

55

|

3200

|

0.004

|

25

|

|

3

|

2

|

3700

|

0.012

|

90

|

3200

|

0.012

|

80

|

2600

|

0.011

|

60

|

2100

|

0.006

|

25

|

|

4

|

2

|

2800

|

0.016

|

90

|

2400

|

0.016

|

80

|

2000

|

0.015

|

60

|

1600

|

0.007

|

25

|

|

5

|

2

|

2200

|

0.020

|

90

|

1900

|

0.021

|

80

|

1600

|

0.018

|

60

|

1300

|

0.009

|

25

|

|

6

|

2

|

1800

|

0.025

|

90

|

1600

|

0.025

|

80

|

1300

|

0.023

|

60

|

1000

|

0.012

|

25

|

|

8

|

2

|

1400

|

0.032

|

90

|

1200

|

0.033

|

80

|

1000

|

0.030

|

60

|

800

|

0.015

|

25

|

|

10

|

2

|

1100

|

0.041

|

90

|

950

|

0.042

|

80

|

800

|

0.037

|

60

|

640

|

0.019

|

25

|

|

12

|

2

|

900

|

0.050

|

90

|

800

|

0.050

|

80

|

660

|

0.045

|

60

|

530

|

0.023

|

25

|

|

14

|

2

|

800

|

0.056

|

90

|

700

|

0.057

|

80

|

570

|

0.052

|

60

|

450

|

0.024

|

25

|

|

16

|

2

|

700

|

0.071

|

100

|

600

|

0.070

|

85

|

500

|

0.075

|

75

|

400

|

0.037

|

30

|

|

20

|

2

|

550

|

0.091

|

100

|

480

|

0.088

|

85

|

400

|

0.093

|

75

|

320

|

0.054

|

35

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIAL

GROUP

材质

|

5

|

6

|

7

|

8

|

|

CUTTING

SPEED

切削速度

|

v=50m/min.

|

v=40m/min.

|

v=100m/min.

|

v=75m/min.

|

|

d

|

z

|

n

|

s,

|

u

|

n

|

s,

|

u

|

n

|

s,

|

u

|

n

|

s,

|

u

|

|

2

|

4

|

8000

|

0.004

|

65

|

6500

|

0.011

|

150

|

16000

|

0.010

|

320

|

12000

|

0.010

|

240

|

|

3

|

4

|

5300

|

0.006

|

65

|

4200

|

0.017

|

150

|

11000

|

0.014

|

320

|

8000

|

0.015

|

240

|

|

4

|

4

|

4000

|

0.008

|

65

|

3200

|

0.023

|

150

|

8000

|

0.020

|

320

|

6000

|

0.020

|

240

|

|

5

|

4

|

3200

|

0.010

|

65

|

2500

|

0.030

|

150

|

6400

|

0.025

|

320

|

4800

|

0.025

|

240

|

|

6

|

4

|

2600

|

0.012

|

65

|

2100

|

0.042

|

180

|

5300

|

0.032

|

340

|

4000

|

0.032

|

260

|

|

8

|

4

|

2000

|

0.016

|

65

|

1600

|

0.059

|

190

|

4000

|

0.042

|

340

|

3000

|

0.043

|

260

|

|

10

|

4

|

1600

|

0.020

|

65

|

1300

|

0.077

|

200

|

3200

|

0.053

|

340

|

2400

|

0.054

|

260

|

|

12

|

4

|

1300

|

0.025

|

65

|

1000

|

0.105

|

210

|

2600

|

0.065

|

340

|

2000

|

0.065

|

260

|

|

14

|

4

|

1100

|

0.029

|

65

|

900

|

0.122

|

220

|

2300

|

0.074

|

340

|

1700

|

0.076

|

260

|

|

16

|

4

|

1000

|

0.037

|

75

|

800

|

0.140

|

225

|

2000

|

0.085

|

340

|

1500

|

0.086

|

260

|

|

20

|

4

|

800

|

0.050

|

80

|

640

|

0.187

|

240

|

1600

|

0.106

|

340

|

1200

|

0.108

|

260

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|