|

|

|

|

|

|

|

Recommended

Cutting Conditions

Drill Inserts (INCH)-CARBIDE

(切削参数)

|

|

|

|

Material

|

Material

Hardness

(Bhn)

|

★

CARBIDE

Grade

|

Speed(SFM)

|

Feed(IPR)

|

|

TiN

|

TiCN

|

TiAlN

|

3/8〞

~1/2〞

|

33/64〞

~11/16〞

|

45/64〞

~15/16〞

|

31/32〞

~1★3/8〞

|

1★13/32〞

~1★7/8〞

|

|

Free

machining Steel

1213,12L13,1215

12L14,1118 etc

|

100

- 150

|

P40

|

330

|

370

|

410

|

0.008

|

0.012

|

0.015

|

0.018

|

0.021

|

|

150

- 200

|

P40

|

290

|

325

|

360

|

0.007

|

0.010

|

0.013

|

0.016

|

0.020

|

|

200

- 250

|

P40

|

270

|

290

|

330

|

0.006

|

0.010

|

0.013

|

0.016

|

0.020

|

|

Low

Carbon Steel

1015,1020,1140

1025 etc

|

85

- 125

|

P40

|

310

|

360

|

390

|

0.006

|

0.009

|

0.012

|

0.015

|

0.019

|

|

125

- 175

|

P40

|

270

|

290

|

350

|

0.006

|

0.009

|

0.012

|

0.015

|

0.019

|

|

175

- 225

|

P40

|

250

|

270

|

315

|

0.005

|

0.008

|

0.010

|

0.014

|

0.018

|

|

225

- 275

|

P40

|

205

|

240

|

275

|

0.005

|

0.008

|

0.010

|

0.014

|

0.018

|

|

Medium

Carbon Steel

1035,1050,1045

1055,1140 etc

|

125

- 175

|

P40

|

270

|

290

|

335

|

0.006

|

0.009

|

0.012

|

0.015

|

0.019

|

|

175

- 225

|

P40

|

245

|

275

|

305

|

0.005

|

0.008

|

0.010

|

0.014

|

0.018

|

|

225

- 275

|

P40

|

215

|

230

|

275

|

0.005

|

0.008

|

0.010

|

0.014

|

0.018

|

|

275

- 325

|

P40

|

185

|

210

|

220

|

0.004

|

0.007

|

0.009

|

0.012

|

0.016

|

|

Structural

Steel

A36,A516,A182 etc

|

100

- 150

|

P40

|

245

|

270

|

300

|

0.006

|

0.010

|

0.012

|

0.014

|

0.018

|

|

150

- 250

|

P40

|

205

|

230

|

245

|

0.005

|

0.009

|

0.010

|

0.012

|

0.016

|

|

250

- 350

|

P40

|

180

|

210

|

240

|

0.004

|

0.008

|

0.009

|

0.010

|

0.014

|

|

Cast

Iron/S,G Iron

A48-76 GR30/GR45

A536-72 60-40-18

A220-76 GR40010 etc

|

120

- 150

|

K20,K10

|

320

|

410

|

450

|

0.007

|

0.012

|

0.016

|

0.020

|

0.024

|

|

150

- 200

|

K20,K10

|

280

|

330

|

410

|

0.006

|

0.011

|

0.014

|

0.018

|

0.022

|

|

200

- 220

|

K20,K10

|

245

|

300

|

365

|

0.006

|

0.009

|

0.012

|

0.016

|

0.018

|

|

220

- 260

|

K20,K10

|

215

|

265

|

305

|

0.005

|

0.007

|

0.009

|

0.012

|

0.014

|

|

260

- 320

|

K20,K10

|

185

|

230

|

260

|

0.004

|

0.006

|

0.007

|

0.009

|

0.012

|

|

Alloy

Steel

8620,4130,4137

4140,6150 etc

|

125

- 175

|

P40

|

260

|

280

|

320

|

0.006

|

0.008

|

0.010

|

0.014

|

0.017

|

|

175

- 225

|

P40

|

240

|

265

|

290

|

0.005

|

0.008

|

0.010

|

0.014

|

0.017

|

|

225

- 275

|

P40

|

215

|

240

|

265

|

0.005

|

0.007

|

0.010

|

0.014

|

0.017

|

|

275

- 325

|

P40

|

205

|

230

|

255

|

0.004

|

0.006

|

0.009

|

0.012

|

0.015

|

|

325

- 375

|

P40

|

175

|

190

|

210

|

0.003

|

0.006

|

0.009

|

0.012

|

0.015

|

|

Tool

Steel

H13,H21,A2,S1 etc

|

150

- 200

|

P40

|

165

|

185

|

220

|

0.004

|

0.006

|

0.008

|

0.010

|

0.012

|

|

200

- 250

|

P40

|

120

|

150

|

165

|

0.004

|

0.006

|

0.008

|

0.010

|

0.012

|

|

High

Temp.Alloy

Hastelloy B,Inconel etc

|

140

- 220

|

K20

|

85

|

90

|

100

|

0.003

|

0.007

|

0.008

|

0.010

|

0.012

|

|

220

- 310

|

K20

|

65

|

75

|

80

|

0.003

|

0.006

|

0.007

|

0.008

|

0.010

|

|

High

Strength Alloy

9840,4340,4330V etc

|

225

- 300

|

P40

|

160

|

180

|

205

|

0.005

|

0.007

|

0.009

|

0.010

|

0.014

|

|

300

- 350

|

P40

|

140

|

160

|

180

|

0.004

|

0.007

|

0.009

|

0.010

|

0.014

|

|

350

- 400

|

P40

|

125

|

140

|

155

|

0.003

|

0.006

|

0.008

|

0.009

|

0.012

|

|

Aluminium

2014,6061,7075 etc

|

30

|

K20

|

1200

|

1300

|

1400

|

0.008

|

0.013

|

0.016

|

0.020

|

0.022

|

|

180

|

K20

|

800

|

950

|

955

|

0.007

|

0.011

|

0.013

|

0.018

|

0.020

|

|

Stainless

Steel

310,316,410,330 etc

|

135

- 185

|

K20

|

165

|

180

|

205

|

0.006

|

0.008

|

0.009

|

0.011

|

0.014

|

|

185

- 275

|

K20

|

125

|

145

|

150

|

0.005

|

0.007

|

0.008

|

0.010

|

0.012

|

|

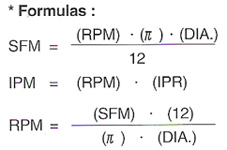

| RPM

= revolution per minute(rev/min) |

|

|

SFM

= surface feet per minute(ft/min)

|

|

DIA

= diameter of drill (inch)

|

|

IPR

= feed rate (in/rev)

|

|

IPM

= inch per minute penetration rate

|

|

The

recommendations for speeds, feeds and other parameters presented

in this chart are nominal

recommendations and should be considered only as good starting

points.Speed and feed

reductions (20% reduction in speed and 10% reduction in feed)

are recommended. |

|

|

|

|

|